Party today! The rotor puller I ordered last month finally arrived after being in transit for over a MONTH, “thank you” United States Parcel Services! They probably sent somebody to swim accros the ocean with my parcel on his back. Judging by the shipping costs, the swimmer had enough food luxury during his trip. I really hope that Pit Posse selects a different shipping company for international orders soon. I took the torch and heated the rotor until water drops put on it boiled, to soften the retainer (lock tight) between the axle and the rotor. Then I re-tightened the rotor puller, smacked it with a hammer, re-tightened it, and so forth. The fifth hit did it, the rotor popped out. As you can see in the first picture, I had a fire extinguisher close by, because oil and fire do not play well together. I also used gloves so I could grab hot metal parts if needed, and I used aluminum plates to protect the magnet from direct heat of the torch.

Party today! The rotor puller I ordered last month finally arrived after being in transit for over a MONTH, “thank you” United States Parcel Services! They probably sent somebody to swim accros the ocean with my parcel on his back. Judging by the shipping costs, the swimmer had enough food luxury during his trip. I really hope that Pit Posse selects a different shipping company for international orders soon. I took the torch and heated the rotor until water drops put on it boiled, to soften the retainer (lock tight) between the axle and the rotor. Then I re-tightened the rotor puller, smacked it with a hammer, re-tightened it, and so forth. The fifth hit did it, the rotor popped out. As you can see in the first picture, I had a fire extinguisher close by, because oil and fire do not play well together. I also used gloves so I could grab hot metal parts if needed, and I used aluminum plates to protect the magnet from direct heat of the torch.

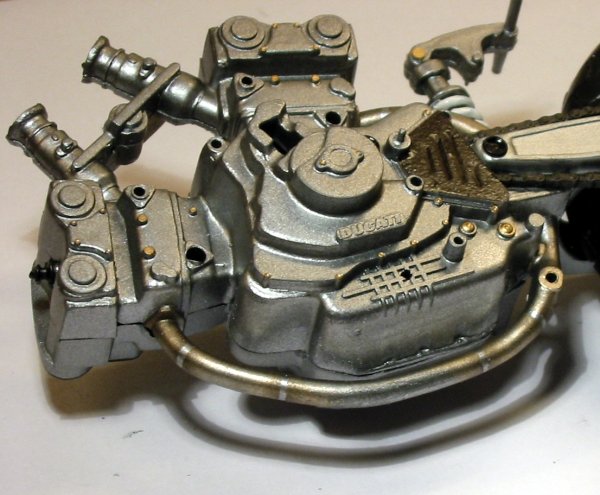

Kawasaki KLR wrenching fanatics will notice the missing balancer chain tensioner (or “doohickey”, as they are sometimes called). Don’t worry, it’s still in one piece, I took it off to straighten it. It was bent and worn by the holding bolt, and I don’t want the bolt to sit or crawl to it’s former spot.

Kawasaki KLR wrenching fanatics will notice the missing balancer chain tensioner (or “doohickey”, as they are sometimes called). Don’t worry, it’s still in one piece, I took it off to straighten it. It was bent and worn by the holding bolt, and I don’t want the bolt to sit or crawl to it’s former spot.

I also checked the valve fittings by putting petroleum in the head. They do not seem to be leaking, and show now signs of abnormal wear. Next week I will be checking the old oil for metal splinters, and putting it all together.

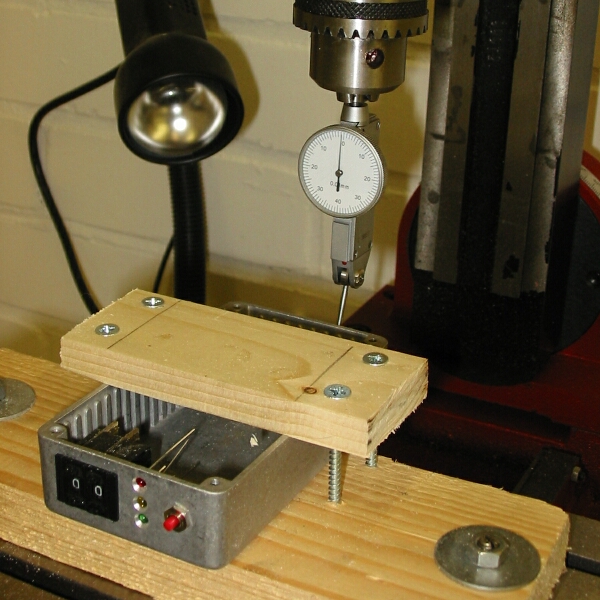

Yes, that’s right. That’s a mill you’re looking at. And yes, that photo was taken at my workshop. Last week I took a couple of days off from work, and decided to do another workshop upgrade session. After buying some decent wrenching tools, I spent some hours on the web looking for a nice bench drill. I was thinking of buying a cheap mill later on, but I found a nice combination of the two at the

Yes, that’s right. That’s a mill you’re looking at. And yes, that photo was taken at my workshop. Last week I took a couple of days off from work, and decided to do another workshop upgrade session. After buying some decent wrenching tools, I spent some hours on the web looking for a nice bench drill. I was thinking of buying a cheap mill later on, but I found a nice combination of the two at the  I made a nice sturdy table for the mill to rest on and bolted it on. It was a bit hard to get the mill on the high table, because it weighs about 45 kilograms and it’s really hard to grab on to. I’ve put a piece of white MDF board on the wall to hold the tools that go with the mill. Putting pieces of wood against the wall to hold tools is terrific. I’ve also done this with the tools for my lathe, see the zundapp image gallery for more pictures of the workshop.

I made a nice sturdy table for the mill to rest on and bolted it on. It was a bit hard to get the mill on the high table, because it weighs about 45 kilograms and it’s really hard to grab on to. I’ve put a piece of white MDF board on the wall to hold the tools that go with the mill. Putting pieces of wood against the wall to hold tools is terrific. I’ve also done this with the tools for my lathe, see the zundapp image gallery for more pictures of the workshop.