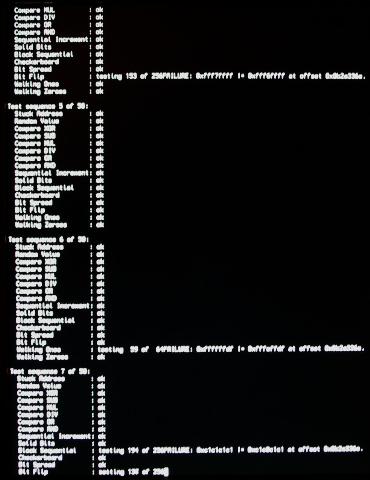

In my last post, the Maxtor OneTouch drive was the prime suspect of the spontanious crashing of the Mac. Tonight the Mac mini crashed again, but this time without the Maxtor connected to it. So I set out to do a thourough memory test in single user mode, running memtest. And after a few iterations it was there: The dreaded memory failure. I guess I have to bring my mini back to the store to get replacement memory.Intermitting problems like this are terrible. They are hard to find, and you loose all trust in your computer, saving every 3 seconds, hoping you don’t loose anything. If the external drive was really to blame, I would seriously have doubted the implementation of the USB drivers, because the system crashes without warning, without logging or anything. A memory failure was actually the more plausible casue all the time, since the kernel just stops because the processor(s) reach a part of the memory where there was supposed to be code, but has become garbage. To be able to log, the processor has to execute code.

In my last post, the Maxtor OneTouch drive was the prime suspect of the spontanious crashing of the Mac. Tonight the Mac mini crashed again, but this time without the Maxtor connected to it. So I set out to do a thourough memory test in single user mode, running memtest. And after a few iterations it was there: The dreaded memory failure. I guess I have to bring my mini back to the store to get replacement memory.Intermitting problems like this are terrible. They are hard to find, and you loose all trust in your computer, saving every 3 seconds, hoping you don’t loose anything. If the external drive was really to blame, I would seriously have doubted the implementation of the USB drivers, because the system crashes without warning, without logging or anything. A memory failure was actually the more plausible casue all the time, since the kernel just stops because the processor(s) reach a part of the memory where there was supposed to be code, but has become garbage. To be able to log, the processor has to execute code.

Category: Hardware

Mac Mini Crash: cause located

Today I spent some more time using Google to find information on why my Mac suddenly crashed. I am now 99% that the cause of this all is my Maxtor OneTouch 250GB drive, which was formatted as one big Fat32 partition (screenshot). Although I connected it to a friend’s iMac for a short period without problems, and it has worked on my Mac mini for a while, I keep finding discussions about people with crashed Macs. I have not installed the Maxtor software, so that’s not the problem.I have disconnected the Maxtor drive last Saturday, and my Mac has been up and running ever since, without problems. I can almost rule out memory related issues, because when I startup Eclipse while running iMovie, iDVD, Thunderbird, Firefox, iTunes, Clutter and TextWrangler (yes all at the same time), the system keeps on running. In fact, it is still responding to user input as if I had only one of those programs running. Only very minimal swapping with 2GB memory, and when swapping, OS X is very efficient about it.

Today I spent some more time using Google to find information on why my Mac suddenly crashed. I am now 99% that the cause of this all is my Maxtor OneTouch 250GB drive, which was formatted as one big Fat32 partition (screenshot). Although I connected it to a friend’s iMac for a short period without problems, and it has worked on my Mac mini for a while, I keep finding discussions about people with crashed Macs. I have not installed the Maxtor software, so that’s not the problem.I have disconnected the Maxtor drive last Saturday, and my Mac has been up and running ever since, without problems. I can almost rule out memory related issues, because when I startup Eclipse while running iMovie, iDVD, Thunderbird, Firefox, iTunes, Clutter and TextWrangler (yes all at the same time), the system keeps on running. In fact, it is still responding to user input as if I had only one of those programs running. Only very minimal swapping with 2GB memory, and when swapping, OS X is very efficient about it.

Now, my plans are as follows:

- Only connect the maxtor to a PC while it is still Fat32.

- Share the drive on the PC, and try to empty it as much as possible (move data to Mac and the fileserver)

- Run Rember in single user mode for a few iterations this weekend to rule out memory problems.

- Decide on a filesystem to use on the Maxtor, and reformat it.

- Re-connect the Maxtor OneTouch to the Mac and see if the gremlin is killed.

It is very likely that the drive is going to be formatted with the “Mac Os Extended” filesystem, but I’m not sure about journalling yet. The disadvantage of all this is that the drive can not be used to transfer files between a PC and a Mac.

Still it feels funny. Some people actually can create 100GB+ Fat32 partitions they can use on their Macs. I can read and write to the drive too, but at some point my Mac decides it has been enough and kills itself (probably after finding the windows crud 😉

Sorry for the linking-frenzy, I had a lot of links I wanted to share with you.

Airbus 330 Entertainent system

Funny thing is, that my wife’s entertainent system actually crashed during flight. It got stuck for about 5 minutes, after which it automatically rebooted, and guess what? I saw a Tux! It is actually a Linux system. A bit of googling revealed that a few people even have seen the system crash on all monitors at the same time. Good thing they aren’t using this system for the flight controls yet. 😉

But it does make sense. It doesn’t cost anything, and being open source, Panasonic (the manufacturer of the system) has full controll on getting all the glitches out. Now they actually do need to do that still, but I bet they got a nice (remote?) update procedure for that. After all, they also need to upload new movies every now and then. Maybe they use the same connection as they use for email? 100% remote update would be nice. No “downtime” for the planes!.

I for one liked the system very much. It actually has games which let you compete with other passengers, but that didn’t seem to be popular on my flights to Las Vegas. I didn’t even had to get my PSP out of my bag 🙂

Now if they only could make those stupid headrests removable so I can put my head back when I want to sleep (like most normal people), flying wouldn’t be all that bad.

Soybean racer

Now that a few school kids have proven that you don’t need oil to race, and several American race series run on methanol (no that’s not an oil product), can we please stop making cars that run on gasoline? And by the way, also stop pumping money into the super-dangerous liquid nitrogen cars? All that is purely to keep the oil companies in the same place: monopoly. Do you really think they do it for the environment? What if I told you that your current petrol car can run on bio-degradable methanol, with almost no changes? If you have a very modern car, the fuel system will even auto-adapt! But noooo, they won’t tell you that, because the oil companies and governements want to keep the monopoly intact!

Not that you can really do anything about it though. Except maybe not buying liquid-nitrogen or hybrid cars. There are better technical alternatives, although not on the market yet. Boycot the “environmentally friendly” car, force them into making a *real* environmentally friendly car.

Yes, I’m driving a diesel, and a motorbike. And no, I’m not worried about oil-shortage. It’s all bullshit from the oil companies, who could have come up with alternatives a long while ago, but chose not to. If there really was an oil shortage, we all would have been driving on methanol for quite some time now. And co2 emmisions would have been reduced to absolutely 0.

How to replace the headlights on a Citroen Xsara

Recently my left headlight broke. I thought I’d change it quickly, but after half an hour of fiddling I decided to ask my dealer to do it for me, while I was looking. That was not a bad idea. It turned out to be not so straightforward after all, and you actually need tools (which you don’t get when buying the car) to do this! This lead me to write a “small” article on how to replace the headlights of a Citroen Xsara. Enjoy.

Read More “How to replace the headlights on a Citroen Xsara” »

You Can’t Fix What You Don’t Measure

… maybe the title should be “Two Stupidities A Week”, but since both stupid actions had to do with measurement, or rather the lack thereof, let’s stick with the proverb.

Rotten Rotor

Last week I tried to pull the rotor by using a rotor puller, and a socket (from a socket wrench set) to block it. The socket burried it’s way into the first thread of the crankshaft. After realising this, I tried to fit the rotor bolt, and it wouldn’t go in. Since only the first thread was damaged, I carefully drilled it out (only needed to go 2 mm deep), and now the rotor bolt fits nicely again.

Last week I tried to pull the rotor by using a rotor puller, and a socket (from a socket wrench set) to block it. The socket burried it’s way into the first thread of the crankshaft. After realising this, I tried to fit the rotor bolt, and it wouldn’t go in. Since only the first thread was damaged, I carefully drilled it out (only needed to go 2 mm deep), and now the rotor bolt fits nicely again.

195Nm Victory!

For some strange reason, my brother’s Kawasaki KLR Tengai dead-stopped. After starting it again, it made some strange noises. It also had lost a lot of oil somewhere along the way, so we decided to not run it again before we found the cause of the trouble. A few weeks ago we encountered a funny problem, we couldn’t loosen the rotor-bolt. In the Kawasaki KLR workshop manual is a picture of a strange wrench to hold the rotor. Ofcourse we’re cheap, so we wouldn’t spring for a nifty and probably expensive Kawasaki specialty tool for a very old bike which not worth more than the petrol that’s in the tank (okay, okay, but you get the point).

For some strange reason, my brother’s Kawasaki KLR Tengai dead-stopped. After starting it again, it made some strange noises. It also had lost a lot of oil somewhere along the way, so we decided to not run it again before we found the cause of the trouble. A few weeks ago we encountered a funny problem, we couldn’t loosen the rotor-bolt. In the Kawasaki KLR workshop manual is a picture of a strange wrench to hold the rotor. Ofcourse we’re cheap, so we wouldn’t spring for a nifty and probably expensive Kawasaki specialty tool for a very old bike which not worth more than the petrol that’s in the tank (okay, okay, but you get the point).

The rotor bolt is tightened to 195Nm. That’s a lot of force there, so it’s not surprising we couldn’t loosen it by holding the flywheeel with our hands. So we set out to create a tool of our own. We even ended up trying to bend an old 32mm Chrome-Vanadium wrench, which resulted in an empty gas can, a very hot workbench and nice colors on the wrench, without it bending even the slightest. We we barely able to heat it to the point it got red-hot, because the metal just conducts the heat away from the point you want to heat.

The rotor bolt is tightened to 195Nm. That’s a lot of force there, so it’s not surprising we couldn’t loosen it by holding the flywheeel with our hands. So we set out to create a tool of our own. We even ended up trying to bend an old 32mm Chrome-Vanadium wrench, which resulted in an empty gas can, a very hot workbench and nice colors on the wrench, without it bending even the slightest. We we barely able to heat it to the point it got red-hot, because the metal just conducts the heat away from the point you want to heat.

So I started mailing with Vincent, a good friend of mine which happens to be “quite handy” with motorbikes . He pointed out that you could also stop the rotor from turning by holding the piston. Because we wanted to measure the play in the bigend bearing we needed to remove the sleeve anyway, so I immediately went back to the workshop to do this. After removing the sleeve, I could easily make some wood pegs to block the piston. The wood would have to have a big surface and be strong enough to hould the piston, without damaging the piston or the engine casing.

So I started mailing with Vincent, a good friend of mine which happens to be “quite handy” with motorbikes . He pointed out that you could also stop the rotor from turning by holding the piston. Because we wanted to measure the play in the bigend bearing we needed to remove the sleeve anyway, so I immediately went back to the workshop to do this. After removing the sleeve, I could easily make some wood pegs to block the piston. The wood would have to have a big surface and be strong enough to hould the piston, without damaging the piston or the engine casing.

It turned out to work great! I needed to attach a long bar to the socket wrench to be able to apply enough force to the bolt, but in the end I got it! In the picture on the left you can see a detail of how the wood blocks are resting on the engine casing. After loosening the bolt, there was absolutely no visible damage to the piston or the engine. Even greater news is that there is also virtually no play on the bigend bearing, so we don’t have to disasemble the crank.

It turned out to work great! I needed to attach a long bar to the socket wrench to be able to apply enough force to the bolt, but in the end I got it! In the picture on the left you can see a detail of how the wood blocks are resting on the engine casing. After loosening the bolt, there was absolutely no visible damage to the piston or the engine. Even greater news is that there is also virtually no play on the bigend bearing, so we don’t have to disasemble the crank.

When looking at the bolt, the results of applying so much force to the faces of the socket wrench become visible. We know for a fact that this bolt has been removed once before, so these wearmarks are from tightening and loosening the bolt just two times. I think we can tighten it one more time, but after that it needs to be replaced.

When looking at the bolt, the results of applying so much force to the faces of the socket wrench become visible. We know for a fact that this bolt has been removed once before, so these wearmarks are from tightening and loosening the bolt just two times. I think we can tighten it one more time, but after that it needs to be replaced.

Server cleaning.

Milling aluminum housing

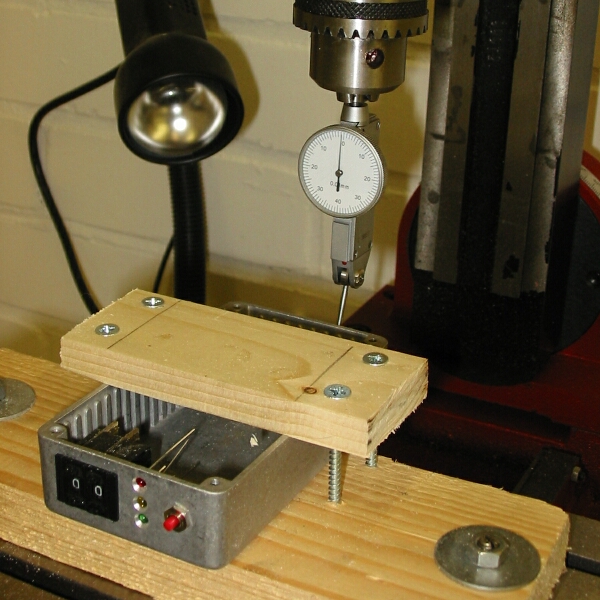

Today I found the first good use for the milling machine. I had this cast aluminum housing for an electronics project, with ridges on the inside. I made a hole for a connector in it, but I never got the nut on the inside flat to the surface because of the ridges on the inside of the housing. I decided to use the mill to flatten the surface on the inside of the housing. The housing did not fit in the clamp, so I had to find a way to get it attached to the bed of the mill in a different way. I took a piece of wood, drilled two holes in it and bolted that to the bed of the mill. Then, I used long plywood screws and another piece of wood to hold the housing. In the picture on the right you can see this construction. I used a test indicator to align the house to the X-axis of the bed.

Today I found the first good use for the milling machine. I had this cast aluminum housing for an electronics project, with ridges on the inside. I made a hole for a connector in it, but I never got the nut on the inside flat to the surface because of the ridges on the inside of the housing. I decided to use the mill to flatten the surface on the inside of the housing. The housing did not fit in the clamp, so I had to find a way to get it attached to the bed of the mill in a different way. I took a piece of wood, drilled two holes in it and bolted that to the bed of the mill. Then, I used long plywood screws and another piece of wood to hold the housing. In the picture on the right you can see this construction. I used a test indicator to align the house to the X-axis of the bed.

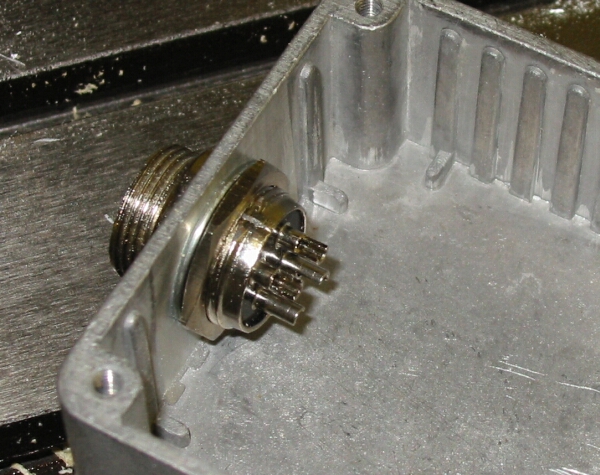

Since I only needed a plane large enough to place a ring and nut on, I roughly adjusted the 6mm mill to just not touch the bottom of the housing. I milled down to the point where the ridges were not visible. The image on the left is the result of the work. The mill is a very nice tool to adjust ready-made electronics housing to your likings.

Since I only needed a plane large enough to place a ring and nut on, I roughly adjusted the 6mm mill to just not touch the bottom of the housing. I milled down to the point where the ridges were not visible. The image on the left is the result of the work. The mill is a very nice tool to adjust ready-made electronics housing to your likings.